What About Seashells?

Nacre is a sub architecture of seashells responsible for maximizing the fracture toughness of the mollusk’s armor. It is a brick-and-mortar topology, as shown above and below, composed out of 95% aragonite and 5% polysaccharide matrix which boasts a fracture toughness 3-9 times greater than homogenous aragonite.

Nacre demonstrates that its mechanical feats don’t come from its materials but how those materials are arranged and their synergy.

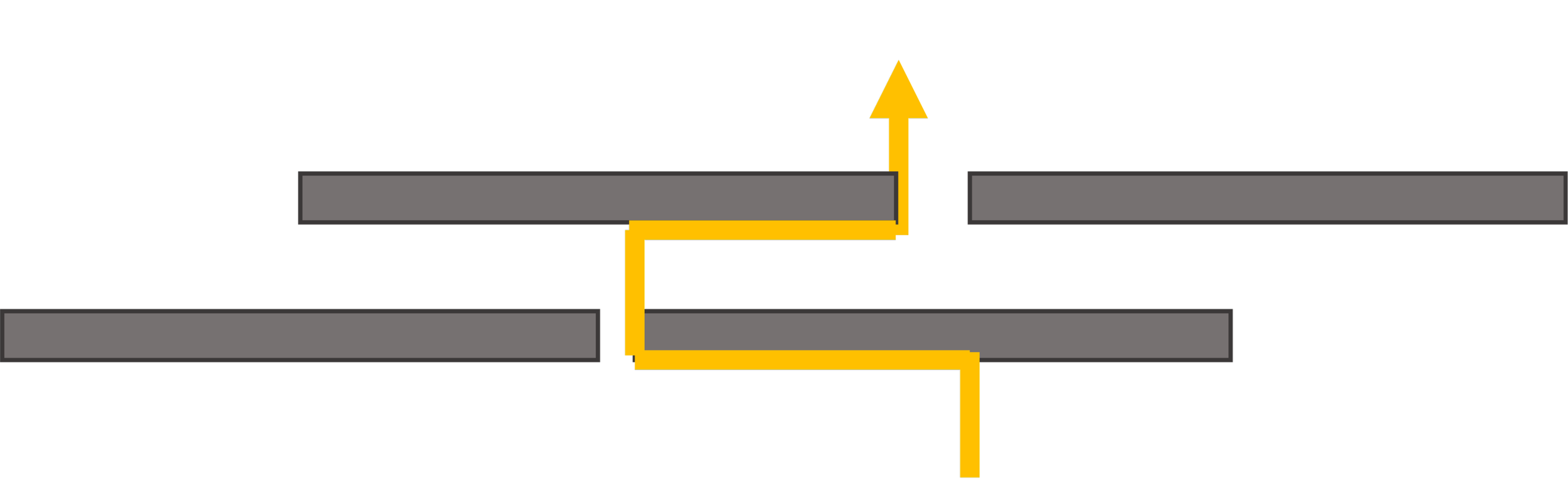

A propagating crack would use less energy to go around the bricks than through them, creating an intrinsic toughening mechanism.

How did I use this?

Following the blueprint of Seashells, I restructured graphene nanocomposites to have a similar brick-and-mortar microstructure. The tensile mechanical tests indicate that overall toughness (energy under the stress-strain curve) increased over 300% as compared to the unstructured microstructure using the same materials.

And experienced a simultaneous increases in stress, strain, and modulus: over 40%, 100%, and 10% respectively.

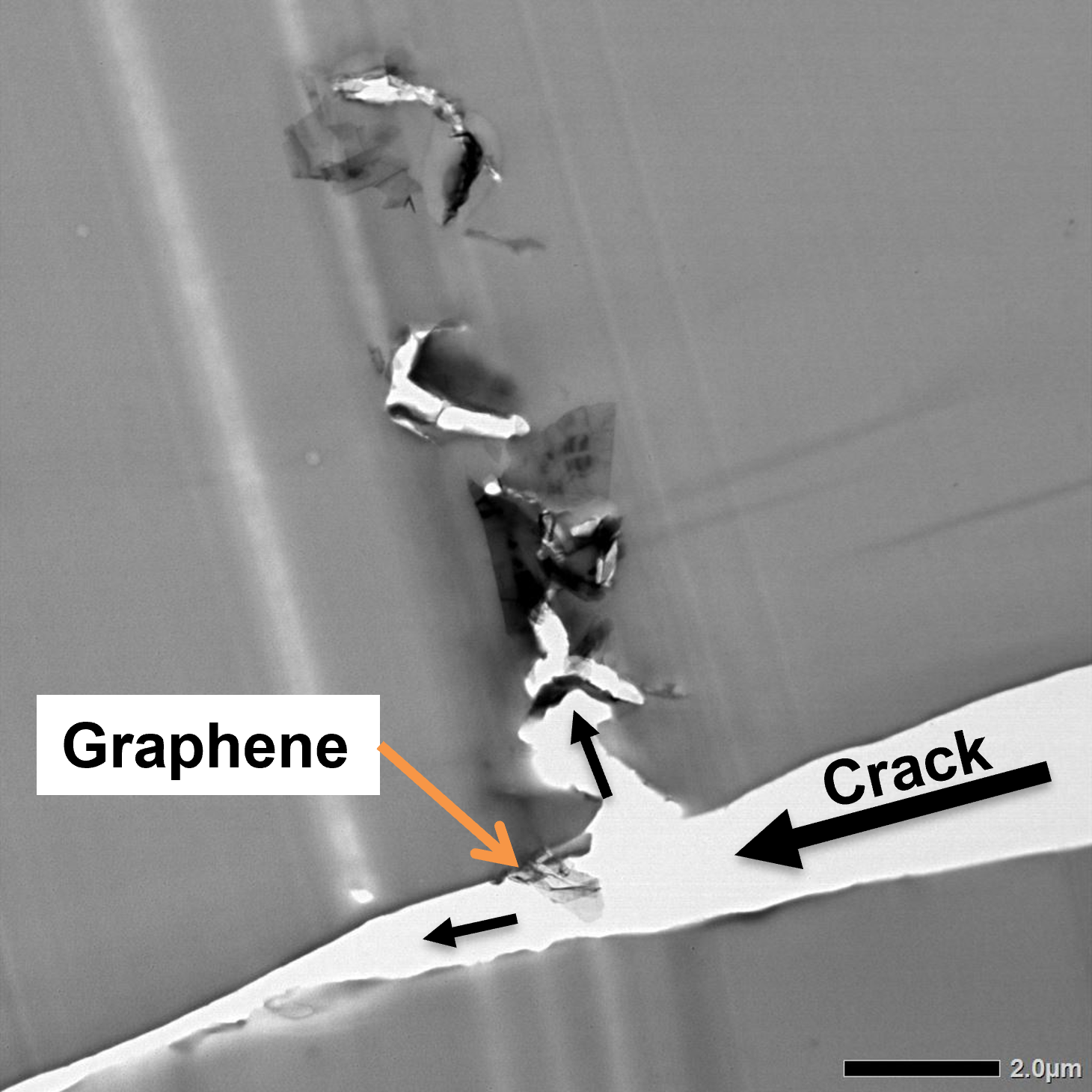

This results in interesting failure modes, check it out below from TEM!

Learn more in “Dielectrophoresis!”

Aligned graphene embedded in Resin

Crack propagates along aligned chain

Crack bridging between platelets

Crack Deflection upon contact with Graphene

Publications:

Incoming…