What’s so cool about Bamboo?

Nature is designed using Composite Materials, one of which is Bamboo!

Bamboo is held together by a polymeric matrix of lignin and hemicellulose and supported by long strands of cellulose fibers. Cellulose fibers are equivalent in strength to glass fiber and are best in tension. Bamboo the composite grows with cellulose fibers placed at the outer ring of the culm where tension is maximum, maximizing their potential!

Cross-Section of Bamboo

Cellulose Fibers Along the Length of Bamboo

How does this Help?

We can recreate composites using these design principles! Placing Fibers where the load is maximum.

In the joining of composite materials, traditional techniques such as bolting are detrimental to the part’s performance, as the bolting process cuts the fibers. By following Bamboo’s design concept, a study was set up to understand the stress flow lines around a hole in a tensile sample using Abaqus FEM software.

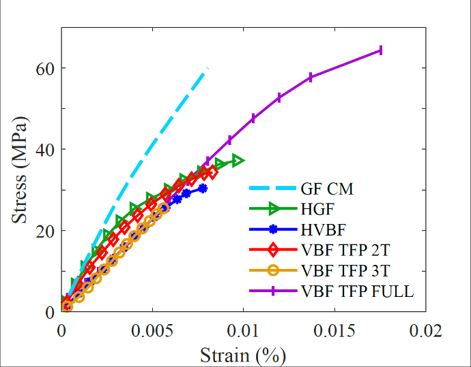

From this understanding, fiber could be placed along those field lines around the hole to maximize its effectiveness. The fibers used were viscose bamboo fiber, which outperformed glass fiber counterparts that were not intentionally designed!

The process used to lay the fiber in a specific arrangement is called TFP (Tailored Fiber Placement), and VARTM was used to infuse the composite.

FEM Stress State

TFP Bamboo Fiber

VARTM Used to Infuse Composite

VBF TFP Full outperforms the HGF (Holed Glass Fiber)

What Else?

Successfully delignified bamboo culms (separated cellulose fibers from its matrix) but viscose bamboo was more suitable for the study.

Cellulose Macrofibers

Delignification Process

Publications:

Korayem, AE.. Kepreos, A.. Haq, M., “Tailored Fiber Alignment in Holed Bamboo Fiber Reinforced Plates.” Journal of Fibers and Polymer Composites. 2025

Korayem, AE., Kepreos, A., Haq, M., “Behavior of Bamboo Fiber Reinforced Composites: Pristine and Damaged.” Conference Proceedings, ASME 2023